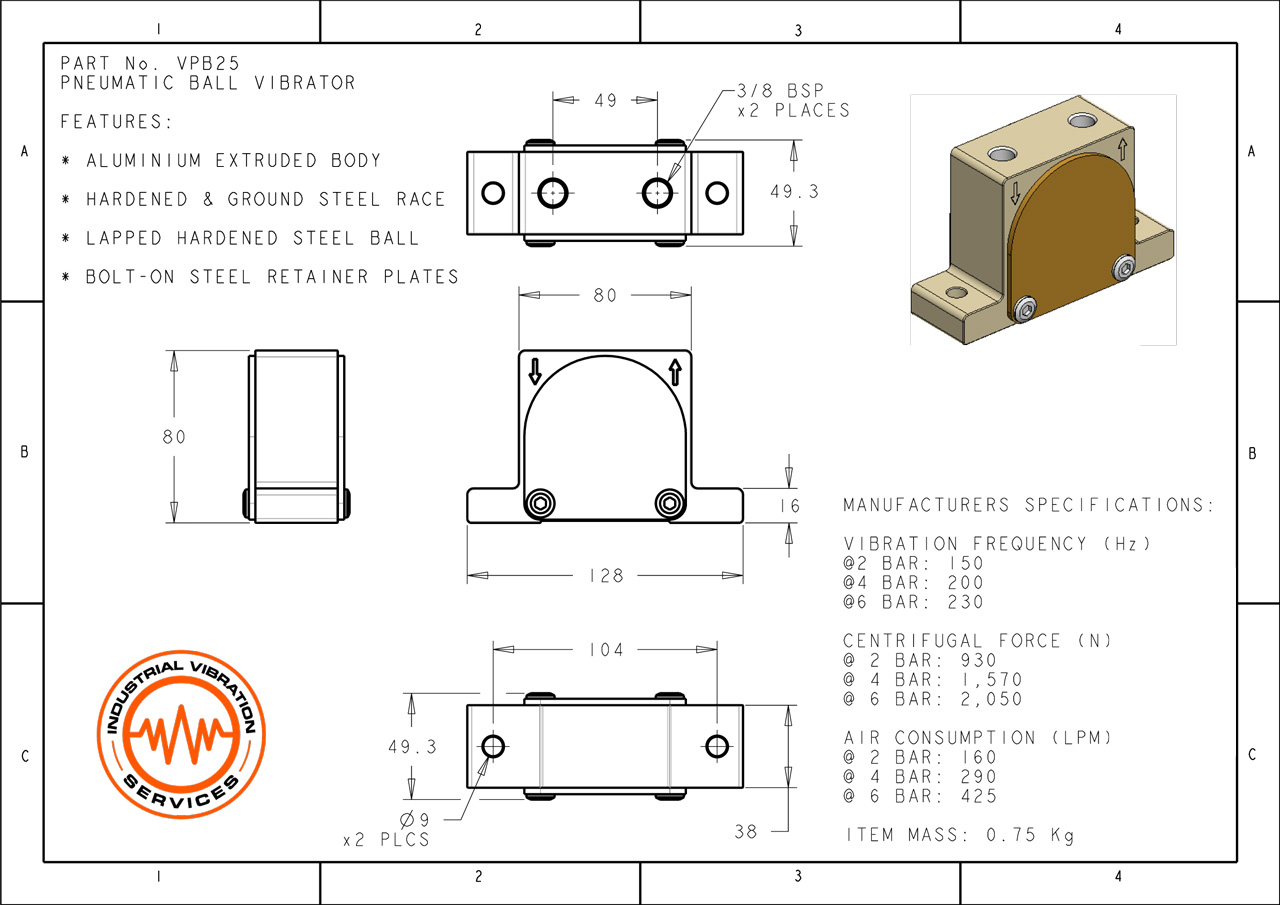

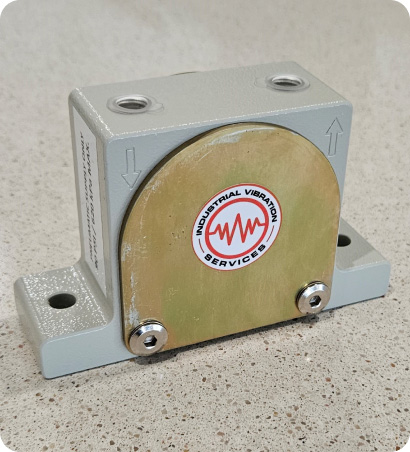

Construction

Aluminium extruded body, durable enamel painted finish. Pressed in, hardened & ground ball race in which a hardened & lapped steel ball runs. The ball is contained in the race via pressed in, low-friction polymer end caps, which are in turn secured via bolt-on, zinc plated, steel plates to prevent the end caps being ejected due to accidental or unwanted pressurisation of the unit.

Working Principle

Compressed air is fed into the inlet port located on the top of the unit. The air drives the steel ball axially around the

race in an unbalanced motion that induces centrifugal force and vibration. A lubricated air supply is recommended to

maximise the service life of the unit.