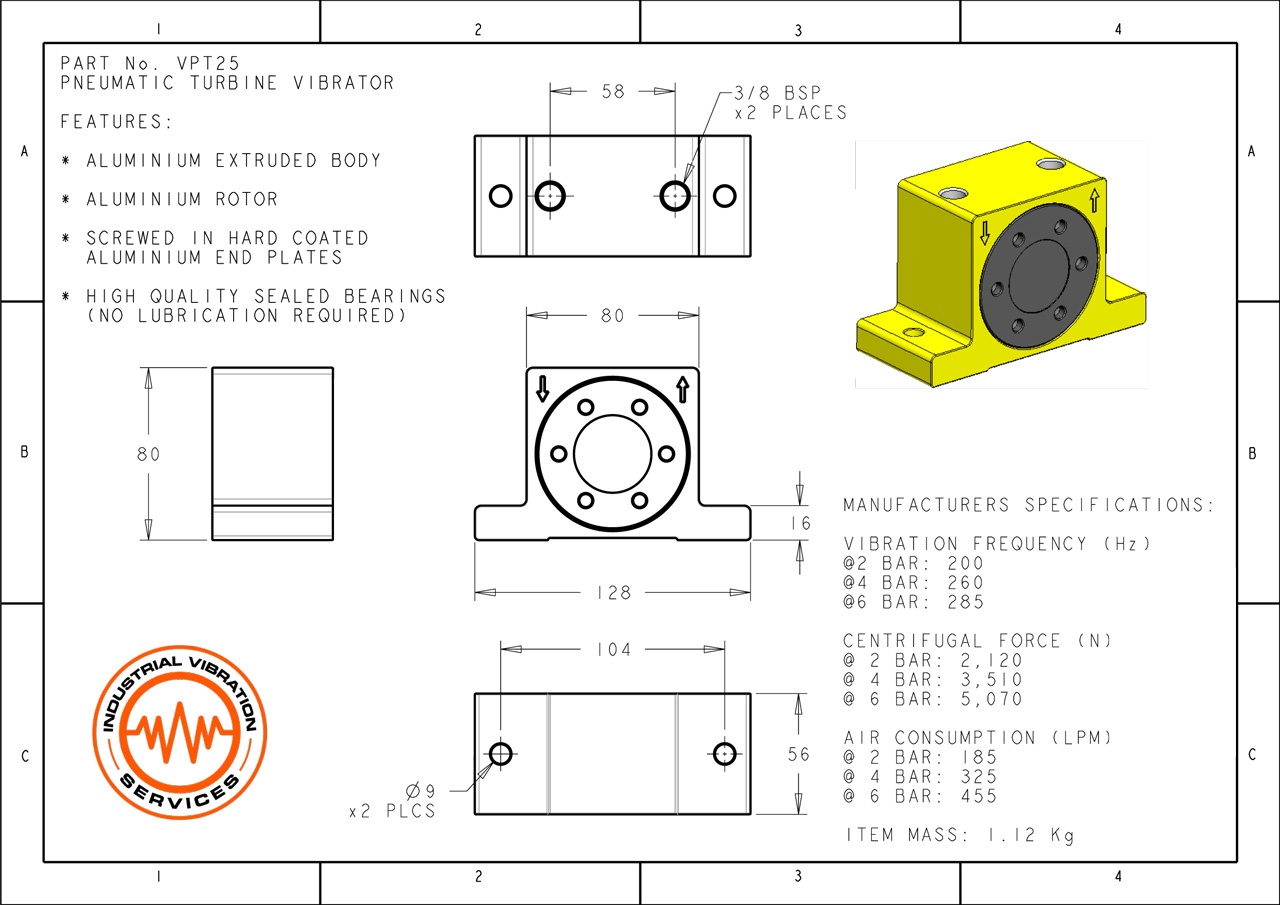

Construction

Aluminium extruded body, durable enamel painted finish. Specially designed fluted turbine with off-set imbalance weights. The turbine is supported by high-speed sealed bearings and the turbine / bearing assembly is retained via screw-in aluminium end plates for precise location & maximum durability.

Working Principle

Compressed air is fed into the inlet port located on the top of the unit. The air drives the turbine via the flutes about the bearing axis. The off-set imbalance weights cause an out of balance motion that induces centrifugal force and vibration. The spent air is expelled through the exhaust port located on the top of the unit adjacent to the inlet port. No lubrication is required (sealed, greased for life bearings).