Selecting Mechanical Vibrators for Bulk Handling

In bulk handling systems, mechanical vibrators play a crucial role in ensuring the smooth flow of materials through hoppers, chutes, and conveyors. Selecting the right mechanical vibrator is essential for optimizing performance, improving efficiency, and reducing maintenance costs. This guide will walk you through the key considerations and steps for choosing the best mechanical vibrators for bulk handling applications.

1. Understanding Mechanical Vibrators

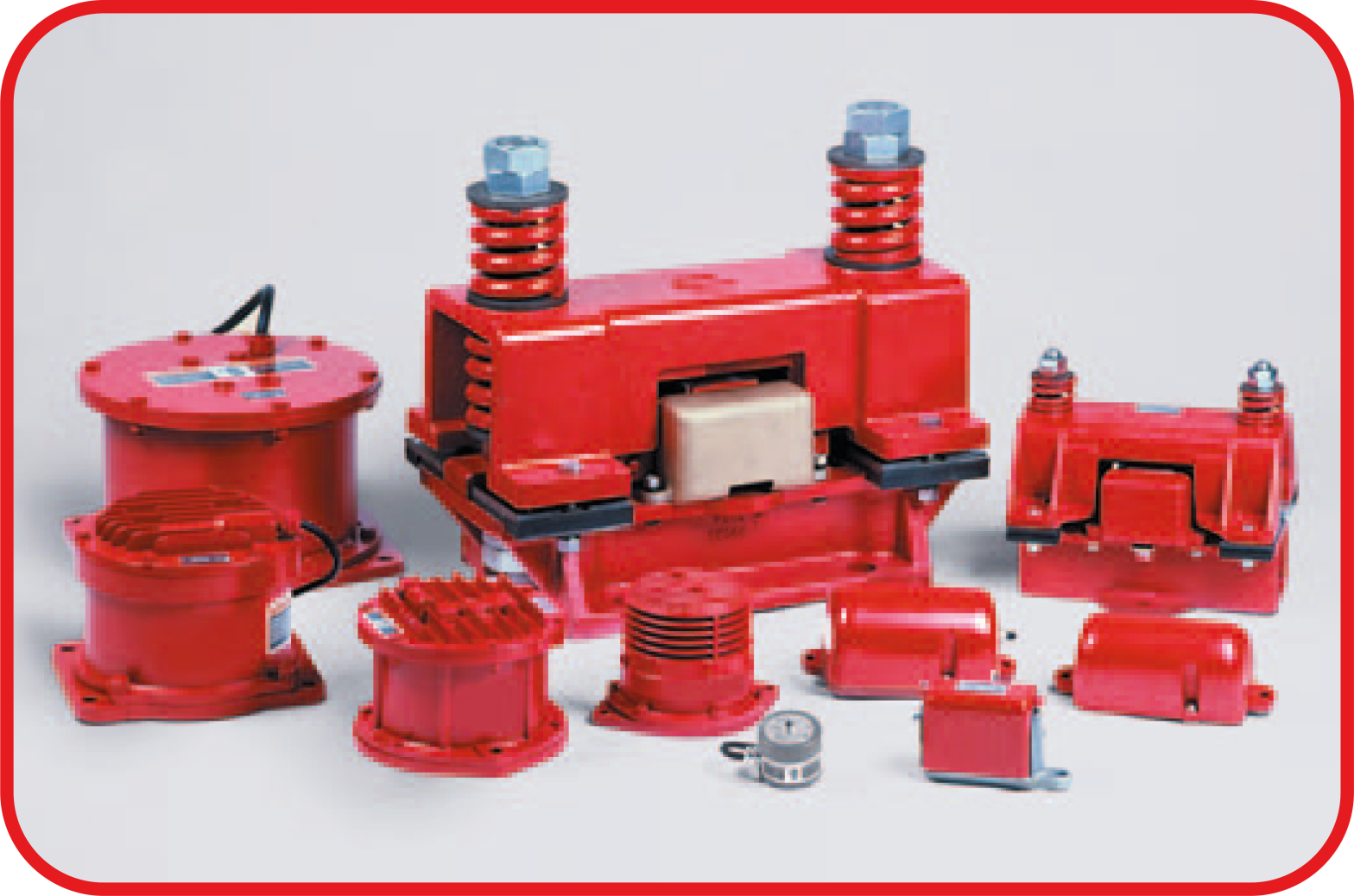

Mechanical vibrators are devices used to generate vibrations to facilitate the movement and handling of bulk materials. They come in various types and configurations, each suited for specific applications and conditions.

1.1. Types of Mechanical Vibrators

There are several types of mechanical vibrators commonly used in bulk handling:

- Electric Vibrators: Utilize electric motors to create vibrations. They are suitable for applications requiring continuous and controlled vibration.

- Pneumatic Vibrators: Operate using compressed air to produce vibration. They are ideal for environments where electrical hazards are a concern.

- Hydraulic Vibrators: Use hydraulic power to generate vibrations. They are often used in heavy-duty applications and where high force is required.

- Rotary Vibrators: Employ rotating eccentric weights to produce vibrations. They are commonly used for material flow in hoppers and chutes.

- Electromagnetic Vibrators: Use electromagnets to create vibrations. They are suitable for precise and adjustable vibration control.

1.2. Common Applications

Mechanical vibrators are used in various bulk handling applications, including:

- Hopper Discharge: To prevent material blockages and ensure a consistent flow.

- Conveyor Systems: To facilitate the movement of bulk materials along conveyors.

- Screening: To aid in the separation of materials in vibrating screens and sieves.

- Compaction: To compact materials in storage bins and silos.

2. Key Factors in Selecting Mechanical Vibrators

When selecting mechanical vibrators for bulk handling, consider the following key factors to ensure optimal performance and reliability:

2.1. Material Characteristics

The properties of the material being handled significantly influence the choice of vibrator:

- Material Density: Heavier materials may require vibrators with higher force output to ensure proper flow.

- Material Granularity: Coarse or fine materials may impact the type and intensity of vibration needed.

- Material Temperature: High-temperature materials may require vibrators designed to withstand extreme conditions.

2.2. Environmental Conditions

Consider the operating environment where the vibrator will be used:

- Temperature Extremes: Ensure the vibrator can operate effectively within the temperature range of your environment.

- Humidity and Dust: Select vibrators with suitable protection against moisture and dust, especially in harsh environments.

- Electrical Hazards: For explosive or flammable environments, opt for pneumatic or explosion-proof vibrators.

2.3. Vibration Frequency and Amplitude

The frequency and amplitude of vibrations required depend on the material and application:

- Frequency: Higher frequencies are generally used for fine materials and lighter applications, while lower frequencies are suited for coarse materials and heavy-duty applications.

- Amplitude: The amplitude of vibration affects the force applied to the material. Higher amplitudes may be needed for more challenging materials or larger flow areas.

2.4. Installation and Maintenance

Ease of installation and maintenance is another crucial consideration:

- Installation: Choose vibrators that are easy to install and integrate into your existing system. Consider the available space and mounting options.

- Maintenance: Opt for vibrators that are easy to maintain and repair. Regular maintenance requirements and the availability of replacement parts should also be considered.

3. Steps to Select the Right Mechanical Vibrator

Follow these steps to select the most suitable mechanical vibrator for your bulk handling needs:

3.1. Assess Your Requirements

Start by evaluating your specific requirements:

- Material Type: Determine the type of material you will be handling and its characteristics.

- Application Needs: Identify the specific application, such as hopper discharge, conveyor systems, or screening.

- Environmental Factors: Consider the environmental conditions in which the vibrator will operate.

3.2. Consult Manufacturer Specifications

Review the specifications provided by manufacturers for various vibrators:

- Technical Data: Compare technical data such as force output, frequency range, and amplitude.

- Compliance and Certifications: Ensure that the vibrator meets relevant industry standards and certifications for your application.

3.3. Seek Expert Advice

If needed, consult with experts or suppliers:

- Supplier Recommendations: Suppliers can provide recommendations based on your specific requirements and application.

- Expert Consultation: Seek advice from industry experts or engineers who specialize in bulk handling and vibration technology.

3.4. Test and Evaluate

Before making a final decision, test and evaluate the chosen vibrator:

- Prototype Testing: If possible, test a prototype or sample in your operational environment to assess its performance.

- Performance Evaluation: Evaluate the vibrator’s effectiveness in handling your materials and meeting your application needs.

4. Conclusion

Selecting the right mechanical vibrator for bulk handling is essential for ensuring efficient material flow and optimal performance in your operations. By understanding the types of vibrators, considering key factors such as material characteristics and environmental conditions, and following a structured selection process, you can make an informed decision that enhances the efficiency and reliability of your bulk handling system. Regular maintenance and expert consultation further ensure that your chosen vibrator continues to perform effectively over time.