The Benefits of Using Turbine Vibrators in Industrial Settings

Turbine vibrators are pivotal in enhancing efficiency and productivity in various industrial applications. These powerful devices harness vibrational energy to facilitate the movement and processing of materials, making them indispensable in many sectors. This article explores the numerous benefits of using turbine vibrators in industrial settings.

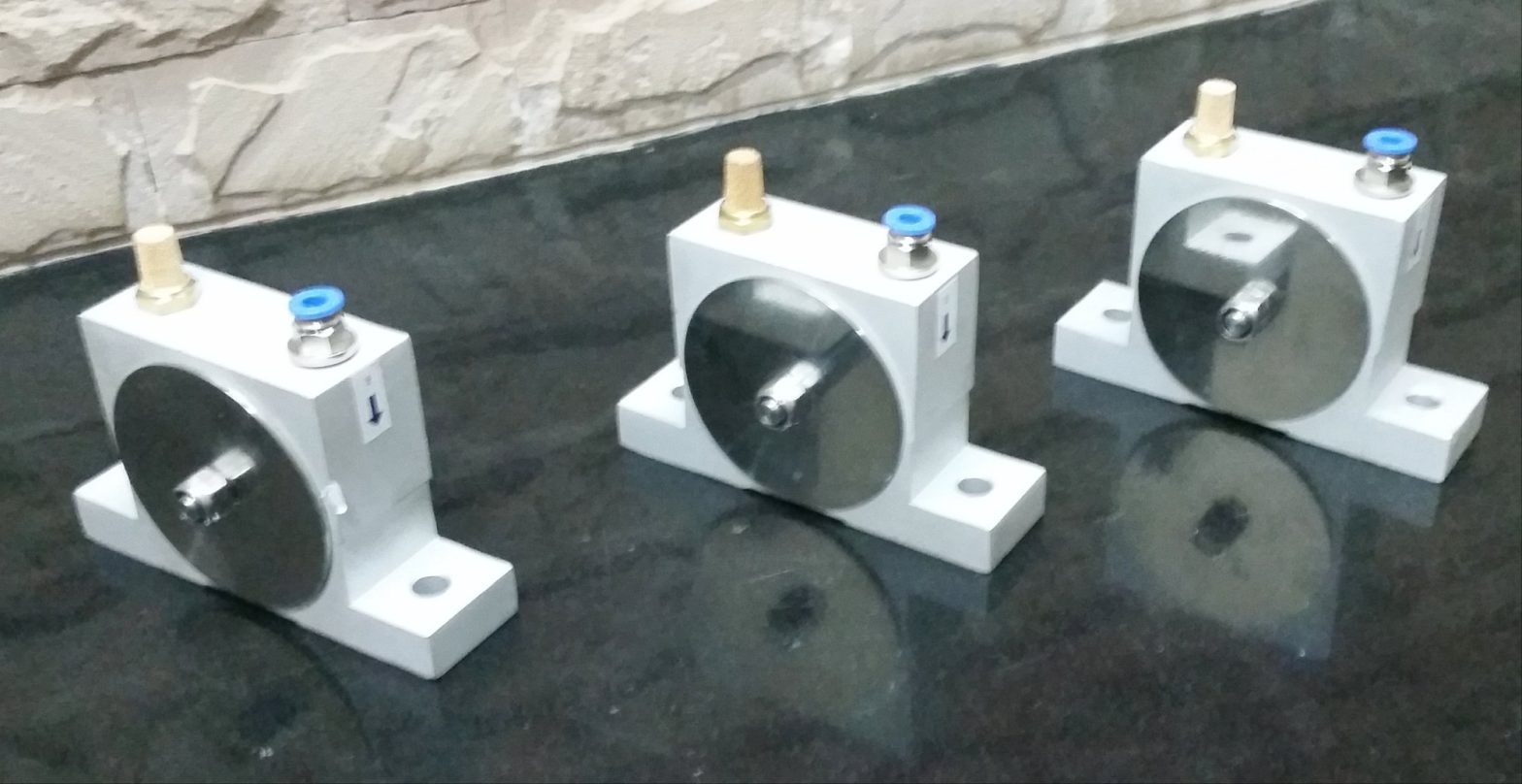

What Are Turbine Vibrators?

Turbine vibrators utilize centrifugal force generated by a rotating turbine to produce vibrations. This mechanism allows for the effective movement of bulk materials, ensuring smooth processing and handling. They are particularly useful in applications requiring consistent material flow and compaction.

How Do Turbine Vibrators Work?

When powered, the turbine within the vibrator spins rapidly, generating vibrations that are transmitted to the surrounding structure or material. This process encourages the movement of materials, helping to prevent blockages and improving overall flow. The intensity and frequency of the vibrations can be adjusted based on the specific application, making turbine vibrators versatile tools in industrial settings.

Key Benefits of Turbine Vibrators

The integration of turbine vibrators in industrial processes offers several advantages:

1. Enhanced Material Flow

One of the primary benefits of turbine vibrators is their ability to enhance material flow in hoppers, bins, and chutes. By reducing friction and promoting movement, these devices help prevent clogs and ensure a steady discharge of materials, ultimately improving operational efficiency.

2. Increased Productivity

With smoother material flow, turbine vibrators contribute to increased productivity in manufacturing and processing environments. By minimizing downtime caused by blockages or material hang-ups, businesses can achieve higher throughput and better utilize their resources.

3. Improved Compaction

Turbine vibrators play a crucial role in applications that require material compaction, such as concrete mixing and soil stabilization. The vibrations generated help achieve optimal density, ensuring the quality and integrity of the final product. This is particularly important in construction and civil engineering projects.

Applications in Various Industries

Turbine vibrators are utilized across a range of industries due to their versatility:

1. Construction and Civil Engineering

In construction, turbine vibrators are essential for compaction processes. They enhance the flow of concrete into molds, reduce air pockets, and improve the strength of concrete structures. Additionally, they are used in soil stabilization, ensuring foundational integrity.

2. Food and Pharmaceutical Industries

In food processing and pharmaceutical applications, turbine vibrators are used to ensure the uniform flow of powders and granules. Their ability to prevent clumping and maintain consistent material flow is critical for maintaining quality and compliance with industry standards.

3. Mining and Mineral Processing

Turbine vibrators are used in the mining industry for material handling and processing. They facilitate the movement of ores and minerals through various stages of processing, improving efficiency and reducing the risk of blockages in conveyors and hoppers.

Cost-Effectiveness and ROI

Investing in turbine vibrators can lead to significant cost savings over time. Here’s how:

1. Reduced Downtime

By preventing material blockages and ensuring consistent flow, turbine vibrators minimize downtime, leading to increased operational efficiency. This reduction in downtime translates into lower operational costs and improved productivity. https://industrialvibration.com.au/turbine-vibrator/

2. Long Lifespan and Low Maintenance

Turbine vibrators are designed for durability and typically require minimal maintenance. Regular inspections and basic upkeep can extend their lifespan, providing a solid return on investment. This longevity contributes to cost savings over the equipment’s operational life.

Choosing the Right Turbine Vibrator

When selecting a turbine vibrator for your industrial application, consider the following factors:

1. Application Requirements

Identify the specific needs of your application, including the type of materials being processed, desired flow rates, and compaction requirements. Understanding these factors will guide you in selecting a vibrator that meets your operational demands.

2. Size and Power

Ensure that the turbine vibrator is appropriately sized for your application and has sufficient power to generate the required vibrations. The size and power of the vibrator should align with the materials’ characteristics and the production volume.

3. Manufacturer Reputation

Choose a reputable manufacturer known for quality products and excellent customer support. Research customer reviews and seek recommendations from industry peers to ensure you’re investing in a reliable solution.

Conclusion

Turbine vibrators are invaluable tools that offer numerous benefits in industrial settings, including enhanced material flow, increased productivity, and improved compaction. Their versatility across various industries makes them essential for optimizing operations and reducing costs. By understanding the advantages and selecting the right turbine vibrator for your specific needs, businesses can maximize efficiency and ensure long-term success.